Concepts Engineered.

Industrialised for Production.

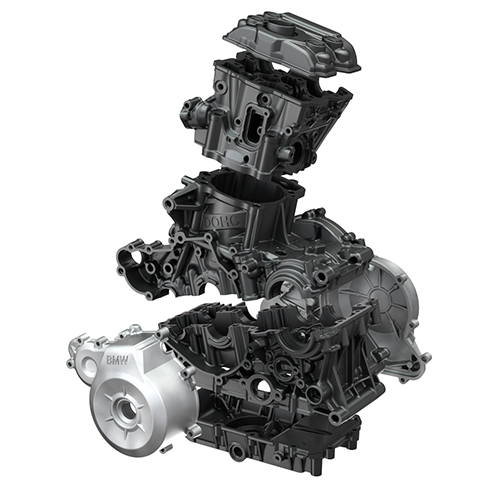

Design of a cost-optimised single-cylinder motorcycle engine for the entry-level segment of BMW.

Production base in India using exclusively local suppliers as well as local materials, local manufacturing processes, thermal treatments and assembly processes.

Outlining of inspection requirements to ensure the production quality.

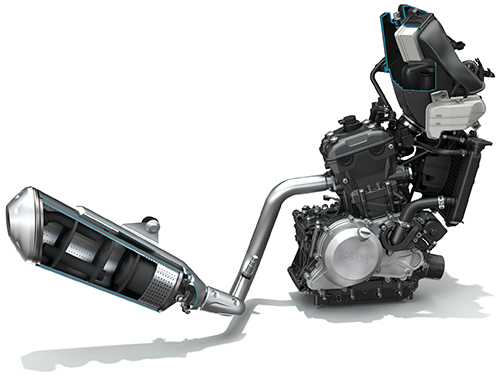

In cooperation with BMW Motorcycle an innovative engine concept for a new vehicle platform was defined.

The special arrangement of the Airbox and exhaust system allowed new solutions for the placement of components in the overall vehicle. Thoughtful solutions such as the Airbox location close to the steering head improve ergonomics for the motorcycle driver and make the motorcycle standing out from its class.

There is no comparable motorcycle on the Indian market.

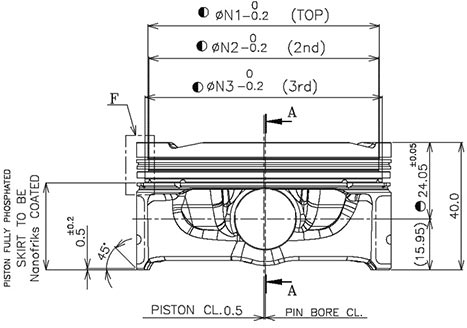

The conceptual layout and calculations considered the locally available materials and manufacturing processes from the very beginning.

One of the main challenges was to combine a modern engine layout with the local production parameters in view of the subsequent series production.

We created a very functional engine layout with innovative detail solutions.

Local production parameters had to be considered with respect to:

A continuous alignment with the single manufacturing departments as well as a refeeding of the test evidences into the single development phases was required.

Production drawings were always made available to all production partners.

All required prototype engines were built at HC-Concepts.

On this base all required engines needed for the engine phases BS1, BS2 and BS3 were continuously improved and tested.

Thanks to an early usage of Indian engine components in the various construction stages the development timeframe could be considerably shortened.

The engines and components had to undergo 300 hours of durability testing before sign off for production.

After gradually defining the local suppliers production engineering modifications could be conceived in detail and could be considered by HC-Concepts for final design.

Close alignments and optimization of single production steps are the prerequisites for a cost-optimized final product.

In particular this was required for:

Not to be underestimated for an industrialization in India are the cultural facts and conditions, which need special attention in view of an efficient implementation. Our longstanding know-how was very useful to make this project a success.

The new BMW motorcycle is now successfully produced in India and sold worldwide.