Concepts Engineered.

Industrialised for Production.

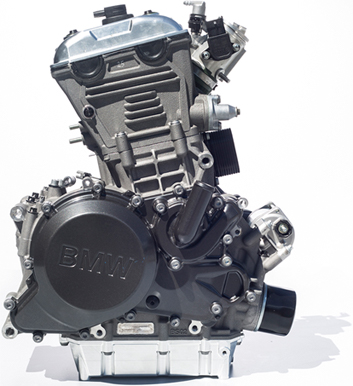

Concept, design & calculation are the core of our business. Covering the wide range from single engine / gearbox assemblies all the way to full engines / hybrid Transmission.

During the concept phase decisive cornerstones, functionally relevant characteristics and the cost frame of the end product are outlined. Thanks to our expertise our concepts achieve high “success rates”, avoiding additional development loops and saving money and time.

For validation of the concept at a very early stage basic calculation can be offered for power simulation, valve train kinematics, FEM structural compound, CFD flows etc. This can be done in- house or it is outsourced.

We offer a wide variety of concepts for different applications:

By involving series suppliers already during the concept phase our concepts achieve a high degree of maturity at an early stage in the development process.

Well done machining drawings ready for manufacturing define the basis for a successful implementation of new serial products.

Carefully prepared design documents – such as 3D-Casting models including all production Details (tool split lines, feeders,…) and machining drawings ready for manufacturing – lay the basis for an efficient transformation of our concepts into hardware prototypes and serial products. An accurate documentation of parts lists, calculations, meeting minutes and reports rounds off our service portfolio.

Thanks to our close supplier network we achieve a production-equivalent quality of our design documents at an early stage of the development phase. The quality of these documents have a vital relevance for a realistic evaluation of the project costs at this stage of the process.

Despite near-production maturity, production feasibility and cost optimisation, we make sure the customer’s requests regarding compact size, weight and performance characteristics are respected and focused upon throughout the entire development process.

Our tools considerably support the entire development process.

Furthermore we dispose of reliable external calculation partners which we use, where appropriate